Forschungsgruppe 5620: Laserauftragschweißen

Funding reference

The research group is funded by the German Research Foundation (DFG) with €3.85 million over the course of four years.

Website

https://www.ruhr-uni-bochum.de/for5620/

Components for industry must be able to absorb large forces while keeping their mass as low as possible. This is where the research group ‘Simulation-based design of production-oriented manufacturing of load-optimised free-form components using laser deposition welding’ led by Prof. Dr. Andreas Ostendorf comes in.

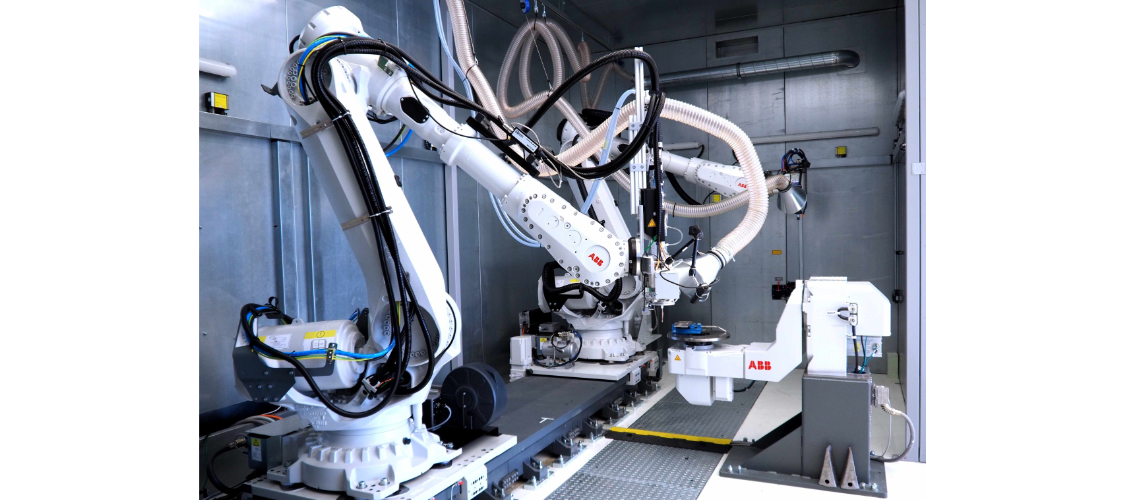

The goal of the research group is to use computer simulations and robot-based laser cladding to develop new geometric freedoms that would not be possible with conventional methods. A 6-axis robot is used for this purpose, which enables flexible material application from any angle. Another 6-axis robot is used for milling post-processing. The experimental work is carried out at our ZESS facility.