Publication on the series production of electrolysers

The Chair of Production Systems at Ruhr University Bochum and the RIF Institute for Research and Transfer are developing an automated conveyor concept for the series production of electrolysers at our ZESS facility. Bernd Kuhlenkötter, Sezer Şahan and Idris Yorgun have published the results of their research in the current issue of Industrial Production e-Paper.

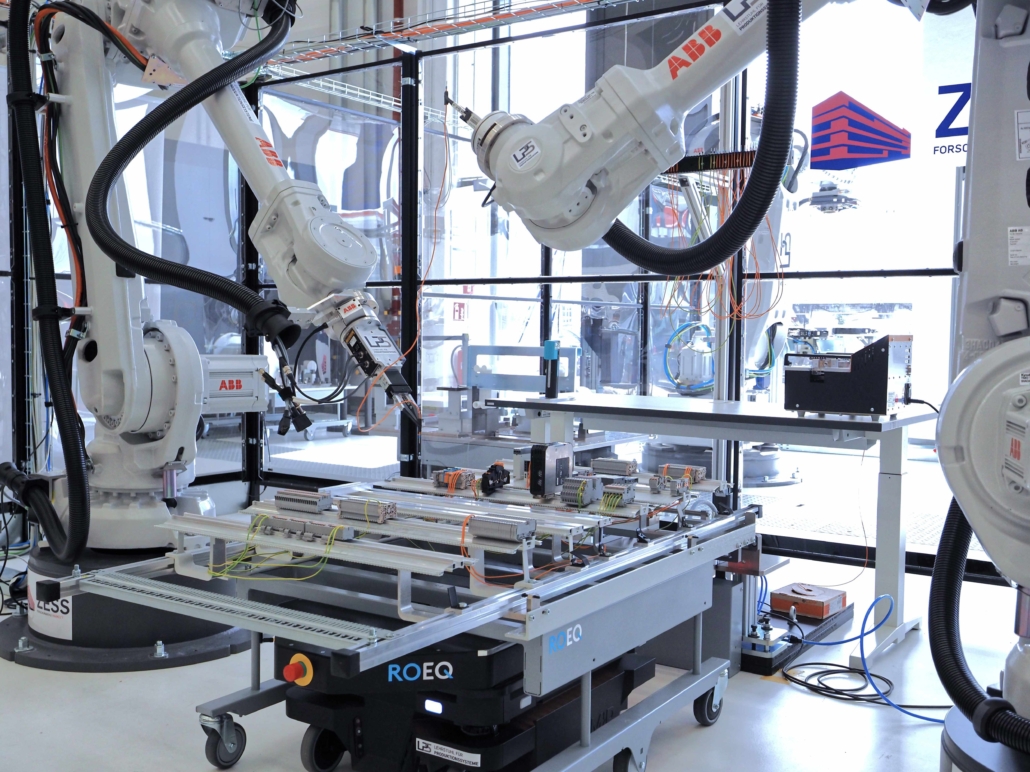

In the logistics concept developed at ZESS, autonomous mobile robot platforms connect the warehouse, the cabling cell and the assembly cell of the electrolyser. The special features of this concept are:

• The mobile platforms communicate with the BIM model of the ZESS. This enables the robots to open doors, call elevators and work across floors independently.

• A precision docking station was designed for exact positioning in the cabling cell, where the robots are optimally positioned. Any remaining deviations are compensated for by the integrated sensors and actuators in the robots of the production cell.

• Special workpiece carriers enable components to be positioned accurately and ensure efficient material flow in automated production.

The concept was developed as part of the H2Giga project. It enables matrix production that is characterised by high flexibility, adaptability and resilience. In this way, a significant contribution can be made to the industrialisation of water electrolysis.

You can find the full article here.